Past and Current Projects

|

Numerical Simulation and Optimization of Time Dependent Processes in Engineering and Materials ScienceModelling and simulation of thermal and mechanical problems in the production of metallic parts can be studied through PDE models and their corresponding numerical simulation. Although simulations are affodable in practice, a further step is needed towards the optimal parametrization of the engineering processes. This binational colaboration projects aims to not only create numerical FEM simulative models, but also embeed the simulations in a multi-objective optimization procedure to answer questions about potentially conflicting optimization goals during the production. Funding: CONACYT and German Academic Exchange Service (DAAD).

|

|

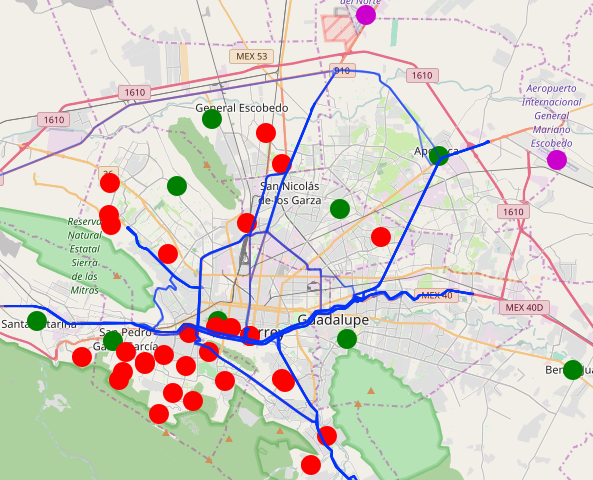

Monterrey Weather Traffic and PollutionData analysis of the self-maintained database for real time weather, traffic and air pollution information of Monterrey's Metropolitan Area, the third largest metro area in Mexico. Funding: CONACYT and CIMAT

|

|

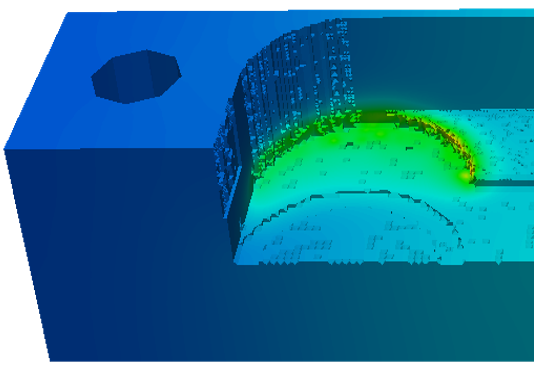

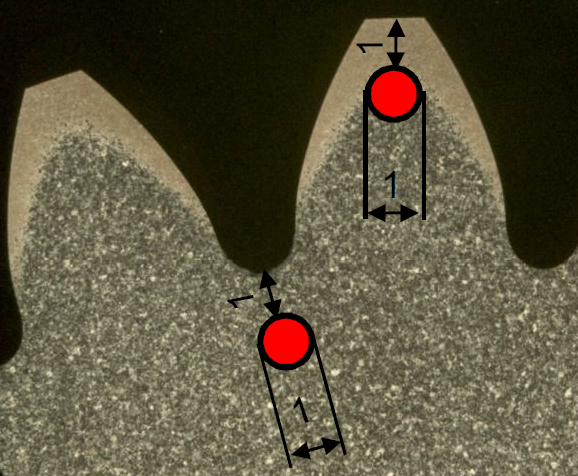

Modeling, Simulation and Optimization of Multi-Frequency Induction Hardening as Part of Modern ProductionModelling and simulation project dealing with the inductive heat treatment of steel gearing components. The models included thermal effects during heating and quenching steel components using an electromagnetic field for the heating and a polymeric solution bath for the quenching sub-processes.The considered models included the electromagneic, thermal, mechanical, and phase transformation equations as a coupled system of ODEs and PDEs which were solved for all times during both heating and cooling processes. Funding: German Research Foundation (DFG).

|

|

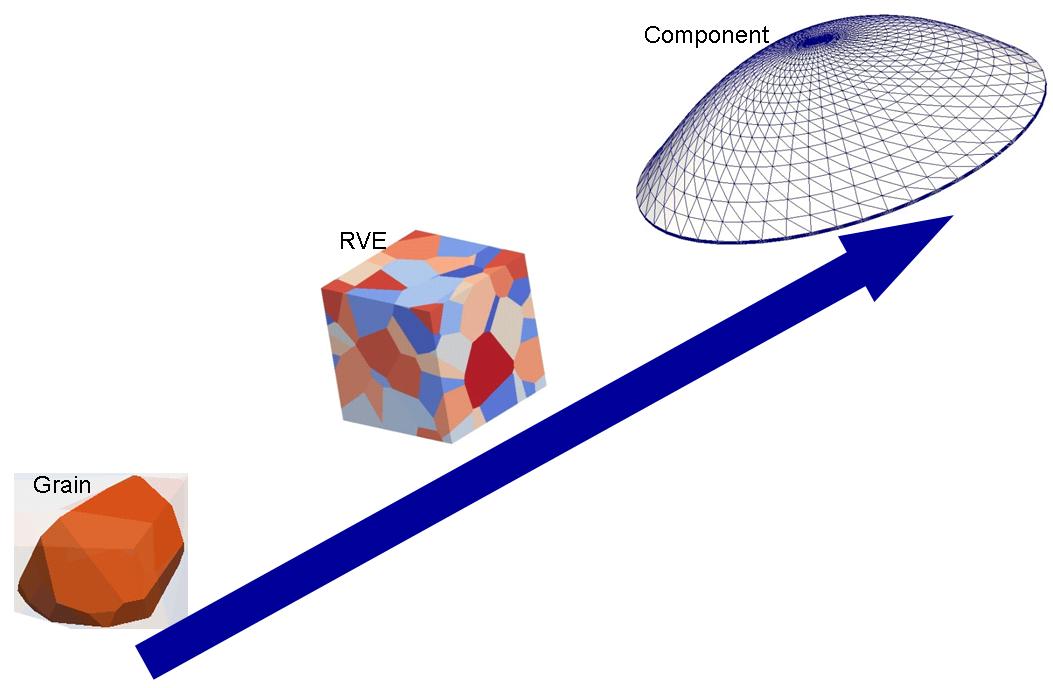

Micro Cold Forming, Subproject "Distribution based Simulation"Works for developing numerical simulation strategies to be used in micro-scale mechanical problems arising when thin metallic plates are used to produce metallic components.The main goal is to consider the existent stochastic variations at the crystallographic scale to embeed this information in a FEM-Model to compute mechanical deformations.This is a Subproject of the Collaborative Research Centre 747, formed with Labs and Human Resources from 8 Research Institutes. Funding: German Research Foundation (DFG).

|

|

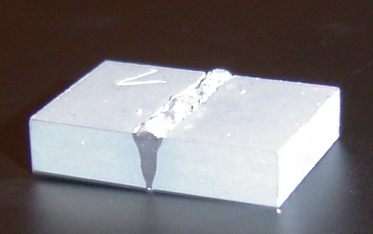

Self optimizing simulation of laser weldingMathematical optimization was used to improve the results of laser welded Aluminum components. The project involved mathematical modelling of the process, the implementation of numerical algorithms of Adaptive FEM, experimental work on real pieces and the calibration of the simulation results.The main topics of the modelling were the role of the so called keyhole (a vapor/plasma region created at the spot where the laser energy enters the material), the solid-liquid material interaction forming the weldpool, and the elasto-plastic mechanic effects which are well known to produce residual stresses in the welded compoents. This project was carried out in cooperation with the Bremer Institute für Angewandte Strahltechnik Funding: ZF Universität BremenGerman Research Foundation (DFG), Mexican National Council of Science and Technology (CONACYT).

|

|

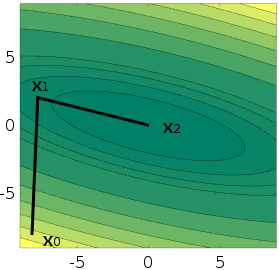

Inverse problems in reconstructing blurred images and image segmentationInternational collaboration between the Center for Industria Mathematics (ZeTeM, Germany) and the Autonomous University of Coahuila (Mexico). In this project, the intersest was on understanding and developing algorithms for finding the most important objects in a given image, using the grpah representation of the image and finding the image cut.Funding: Mexican National Council of Science and Technology (CONACYT) and German Academic Exchange Service (DAAD).

|

|

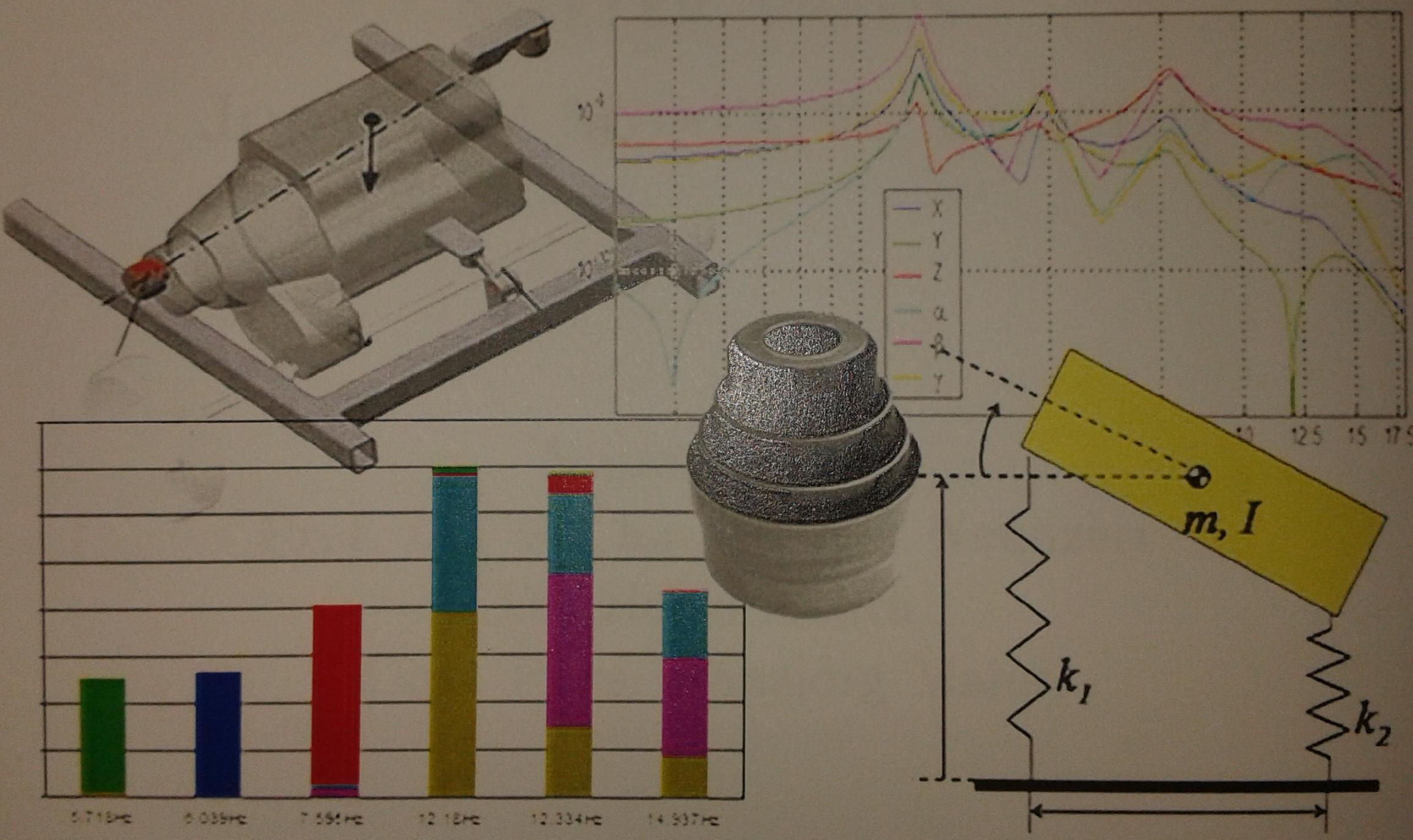

Analysis and Optimization of an Engine Mounting System with respect to ComfortModelling of the interactions involved in the mounting system of a car engine. The goal was to determine if the mounting points could be modified to reduce the vibration passing from the engine motion towards the chassis, as this can have an undesired effect in the passenger comfort.Funding: Tech Development Centre of the company Freudenberg Dichtungs-und Schwingungstechnik KG, Weinheim Germany.

|

|

Numerical iterative mehthods for large-scaled least squares problemsWork describing the main ideas behind iterative solvers for linear systems of equations with a strong focus on Conjugate Gradient based methods. The ideas, algorithms and implementation was performed and used for solving large scaled systems arising from least squares problems. The implementations were also compard in terms of convergence rates for some selected problems.This work was awarded with the "Sotero Prieto" award from the Mexican Mathematical Society (SMM).Funding: Universidad Nacional Autónoma de México (UNAM) and Universidad Autónoma de Coahuila, Mexico.

|

CONACYT

CONACYT CIMAT

CIMAT Foro Consultivo de CyT

Foro Consultivo de CyT SMM

SMM @cimatoficial

@cimatoficial CIMAT_Monterrey

CIMAT_Monterrey Wikipedia

Wikipedia